Lintels are an essential structural element wherever there is an aperture in a wall. The wall above most doors and windows is supported by a lintel. The majority of lintels used in the UK are made from steel.

What standards apply to lintels?

Steel lintels should be manufactured and tested in accordance with BS EN 845-2:2013 Specification for ancillary components for masonry Part 2: Lintels. This standards applies to lintels up to a maximum length of 4.5m. In addition, steel fabrications for structural use, which includes lintels, are required to be CE marked to EN 1090. Other standards apply and so it is always better to source lintels from a reputable UK manufacturer.

What protective coatings are applied to lintels?

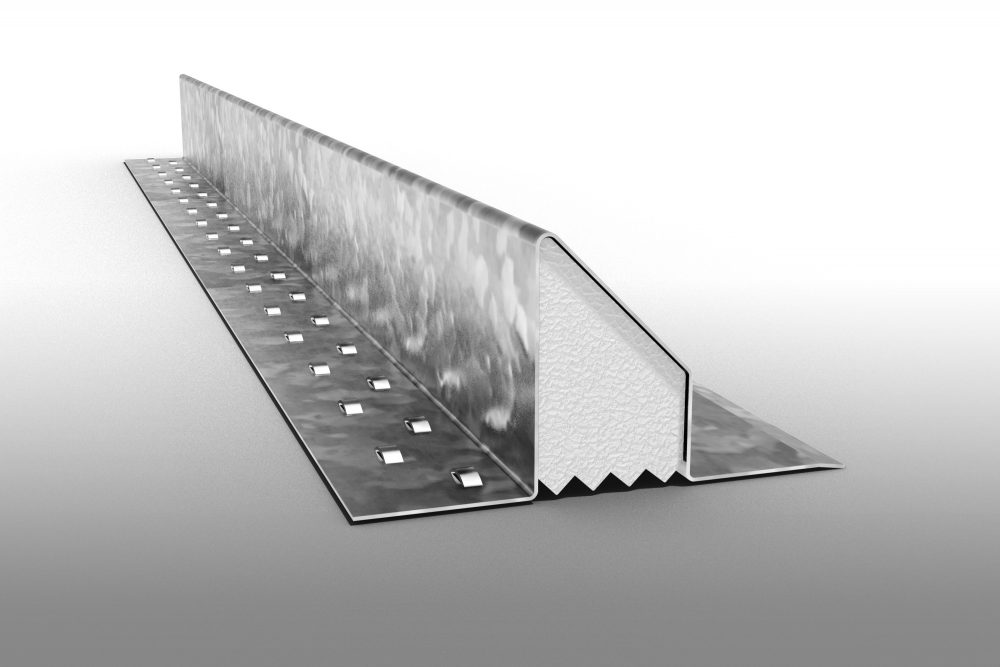

Our lintels are the only product range to be fully hot-dip galvanized after manufacture. Carrying out this process after they have been manufactured ensures that every part of the lintel is covered with an equally effective layer of protection.

Some lintels are manufactured using pre-galvanised material, which is cut, bent and processed before a layer or paint is applied to protect the cut surface. However, it is these cut surfaces that are at greatest risk of damage, which is why our cut edges are protected by metal galvanising rather than paint.

Recent changes to Building Regulations mean that a building’s fabric performance must now hit a Target for Fabric Energy Efficiency (TFEE) in addition to the traditional Target Emission Rate (TER) for CO2. This means that more emphasis is put on reducing heat loss, a significant proportion of which can be attributed to lintels and other non-repeating thermal bridges.

Latest generation lintels such as our Supatherm range are able to achieve a Psi value of between 0.03 and 0.06. The lower the Psi value, the better the thermal performance.

How do I calculate the thermal performance of a lintel?

We have developed a new PSI Value Calculator, accessible via PC, tablet or mobile, which is capable of instantly presenting thermal transmittance data on our Supatherm range of high performance lintels.

All users have to do is input cavity width, block and insulation details, along with lintel length, for the tool to provide the required PSI value in W/mK.

Why is the Psi value important?

Energy assessors, when working on a building constructed to Part L Accredited Construction Detail, tend to use an approved value of 0.3W/mK for lintels without a baseplate. In reality, a heat loss of 0.3W/mK makes the assumption that the line of insulation is interrupted with a highly conductive, traditional steel lintel.

However this does not reflect actual heat loss from latest generation, thermally broken lintels. For example, even with our 1500mm standard lintel the Psi Value is 0.18 W/mK, although upgrading to our Supatherm lintel at the same length improves thermal performance to between 0.041 0.073 W/mK. Replacing a traditional lintel made from a single piece of metal with a thermally broken lintel can therefore cut heat loss through thermal bridging by over 75% and make significant improvements in SAP calculations.

Where are PSI Values used?

PSI values are used by energy assessors in their SAP calculations, meaning they avoid modelling heat loss on the insulation being interrupted by a highly conductive, traditional steel lintel, which can have a PSI of around 0.3W/mK. If the assessor uses 0.3W/mK rather than determining the correct Psi value through a calculator it can result in an incorrect measure of the building’s actual performance.

In terms of actual performance, a thermally broken lintel can improve both the dwellings CO2 emission rate (DER) and fabric energy efficiency rate (DFEE) by 3% and 1% respectively.

What are the practical benefits of super insulated lintels?

In the case of a small detached dwelling of around 105m² the reduction in heat loss from a thermally broken lintel is equivalent to upgrading from a double to a triple glazed window. The impact of upgrading to a super-insulated lintel is even greater on a larger detached dwelling of 304m², which can mean the cavity wall thickness is reduced from 150 to 125mm. This is another significant saving for your customer in terms of insulation and masonry ancillaries. It also avoids the loss of internal living space as wider cavities have a tendency to encroach on the internal footprint.

Where can I purchase high performance lintels?

Our Supatherm range of lintels are available from merchants and stockists around the UK. We offer a range of bespoke options on request. To find our nearest stockist, click here.